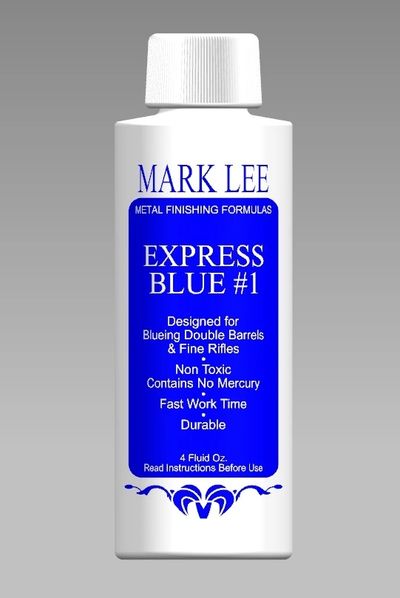

EXPRESS BLUE#1

MARK LEE EXPRESS BLUE #1 - INSTRUCTIONS

Wear safety glasses during all processes.

METAL PREPARATION

Metal Preparation Tools Required:

• Abrasive paper, cloth-backed 120 to 400 grit

• Selection of files or polishing stones

Remove pitting with files, polishing stones, or abrasive paper. Complete metal preparation using 320 to 400 grit abrasive.

DEGREASING

Degreasing Tools Required:

• Detergent (Simple Green® recommended)

• Scrub brush & Scotch-Brite pad

• Tongs or wire hooks

• Air compressor or paper towels

• Clean cotton gloves

• 2 Containers (1 for clean water & 1 for soapy water)

Degreasing is essential in getting fine results. Soak parts in hot soapy water using a cleaner such as Simple Green®. Scrub parts with a brush during the cleaning process. Remove parts from the cleaning solution with tongs or hooks.

Place cleaned parts in fresh hot tap water and lightly scrub with a Scotch-Brite pad to remove all residue. Remove from water and dry with compressed air or blot with paper towels. Wear cotton gloves while handling degreased metal parts. Do not touch cleaned parts with bare hands.

ETCHING (Optional)

Etching Tools Required :

• Sandblasting gun

• 150 grit garnet (aluminum oxide can be used)

Etching helps first applications take hold of base metal. Blast with 150 grit garnet at 30-40 psi. The polished metal will appear dull gray after blasting but the process of rust bluing will bring the sheen back. The blasting is best performed after degreasing, and parts should only be handled with clean cotton gloves.

APPLICATION

Application Tools Required:

• Vinyl or latex gloves and cotton gloves

• Natural sea sponge, cellulose sponge, cotton swabs, or poly foam paint brush

• Small glass or plastic container

• Propane torch or other heat source

• Stainless steel container for boiling distilled or deionized water. Tap water can be used in many parts of the country but depends on mineral content in your area.

• Steel wire brush (.003-.005” bristles) or oil free super fine steel wool

Pour solution into small glass or plastic container. Warm metal parts to 150-200° F with propane torch or other heat source. Use vinyl or latex gloves during application. Dip applicator in solution and apply to warmed metal parts. A coating of brown to yellow rust will immediately form. Coat 2 more times, drying the coating with the flame each time. Submerge part in boiling water for 2 minutes, remove from water and dry with compressed air or paper towels.

The boiling water converts the red-rust to black-rust. Wearing clean cotton gloves, remove powdery residue with steel wool or fine wire brush. The coating is very tough so do not be afraid of carding. Examine metal under incandescent light bulb or sunlight. If you see any shade of brown or purple, card the metal until the metal is silver, gray, or black. The finish will even out with each application. Warm the metal parts again and coat with solution 3 times. Boil in water again to convert the red-rust to black. Remove from water, dry, card. Repeat this process of coating, boiling, and carding 6 to 10 times. When satisfied with the metal finish, oil parts and coat the bluing with rust inhibiting grease (RIG) and allow to set for 24 hours. The final neutralizing step below is unnecessary if you have boiled the last few coats in clean fresh water.

NEUTRALIZING (See Note)

Neutralizing Tools Required:

• Baking soda and water

• Container large enough to submerge the parts

NOTE: This step should be eliminated if fresh water was used to boil the last few coats. When satisfied with metal finish, place parts in a container with a solution of baking soda and room temperature tap water (any concentration) for 5 minutes. Rinse parts, dry and coat with rust inhibiting grease (RIG) and let set for 24 hours.

TIPS

- During the whole bluing operation don't touch the metal with your bare hands as you can leave contamination spots in the finish.

- After the first boiling and carding, examine the metal under the light of a regular light bulb or sunlight. If you see any shade of brown or purple card the metal until the metal is silver, grey, or black. Applying more coats over the top of bad color will lock it in. You usually won't see it happen again after the first boiling and carding.

- If you have a very small spot along a rib that doesn't want to take color, take a piece of new 400 grit paper and scuff the small area. The next coats should take.

- If you use steel wool, make sure to buy oil free steel wool. It is available at fine woodworking stores or on the internet.

- Heat a practice piece of steel, swabbing the solution with a poly foam paint brush 5 or more coats, reheating when necessary. Coat the part like you are trying to ruin it. I think you'll be surprised with the results.

- Garnet is preferred for etching (blasting) as it is unlikely to imbed in the metal. This is only a concern on parts that rub against each other such as the bolt.

- Do not try to blue the ends of a barrel because you don't want to get any bluing solution in the bore. Polish the barrel crown back to white after bluing. I don't plug the bores but I do make sure I'm using fresh water when doing barrels.

- I have found that I can usually repair rust blued finishes without stripping the whole part. Polish only the problem area. Coat the repaired section and when the color matches, recoat the whole part with one or two coats.

- Using the rust blue to touch up damaged screw heads works well and the bluing won't rub off.

- If you don't have a boiling tank and are only going to do a few guns you can buy a piece of PVC pipe, glue a cap on one end, hang your barrel in the pipe and fill the pipe with boiling water.

- Parts can be strung on a piece of wire for boiling but don't wire brush the parts with the wire attached. I almost lost an eye when the wire brush grabbed the string of parts.

- After initial cleaning, a light scrub down with 3M Scotch-Brite pad while in the water rinse is often helpful to insure that all the cleaner residue is removed.

- Sometimes carding with steel wool and water can blend a streak in the blued finish. Some finishers prefer to use water and steel wool in all carding operations.

- Rust bluing can be lightly buffed with a loose muslin wheel and a compound used for mirror finishing. This adds a little sheen to the finish. This operation can be done just before applying grease or oil to the finished parts.

- Don't use WD-40 on fresh rust blued parts. The WD-40 can remove some of the finish.

EXPRESS BLUE #1

EXPRESS BROWN#2

MARK LEE EXPRESS BROWN #2 - INSTRUCTIONS

Wear safety glasses during all processes.

METAL PREPARATION

Metal Preparation Tools Required:

• Abrasive paper, cloth-backed 120 to 400 grit

• Selection of files or polishing stones

Remove pitting with files, polishing stones, or abrasive paper. Complete metal preparation using 320 to 400 grit abrasive.

DEGREASING

Degreasing Tools Required:

• Detergent (Simple Green® recommended)

• Scrub brush & Scotch-Brite pad

• Tongs or wire hooks

• Air compressor or paper towels

• Clean cotton gloves

• 2 Containers (1 for clean water & 1 for soapy water)

Degreasing is essential in getting fine results. Soak parts in hot soapy water using a cleaner such as Simple Green®. Scrub parts with a brush during the cleaning process. Remove parts from the cleaning solution with tongs or hooks.

Place cleaned parts in fresh hot tap water and lightly scrub with a Scotch-Brite pad to remove all residue. Remove from water and dry with compressed air or blot with paper towels. Wear cotton gloves while handling degreased metal parts. Do not touch cleaned parts with bare hands.

ETCHING (Optional)

Etching Tools Required:

• Sandblasting gun

• 150 grit garnet (aluminum oxide can be used)

Etching helps first applications take hold of base metal. Blast with 150 grit garnet at 30-40 psi. The polished metal will appear dull gray after blasting but the process of rust bluing will bring the sheen back. The blasting is best performed after degreasing, and parts should only be handled with clean cotton gloves.

APPLICATION

Application Tools Required:

• Vinyl or latex gloves and cotton gloves

• Natural sea sponge, cellulose sponge, cotton swabs, or poly foam paint brush

• Small glass or plastic container

• Propane torch or other heat source

• Steel wire brush (.003-.005” bristles) or oil free super fine steel wool

• Stainless steel container for boiling distilled or deionized water. Tap water can be used in many parts of the country but depends on mineral content in your area.

Pour solution into small glass or plastic container. Warm metal parts to 150-200° F with propane torch or other heat source. Use vinyl or latex gloves during application. Dip applicator in solution and apply to warmed metal parts. A coating of brown to yellow rust will immediately form.

Coat 2 more times, drying the coating with the flame each time. Wearing clean cotton gloves, remove powdery residue with steel wool or fine wire brush. The coating is very tough so do not be afraid of carding. The metal should now be an uneven brown coating. The finish will even out with each application. Warm the metal parts again and coat with solution 3 times. Card off loose residue and repeat steps of coating and carding until it’s difficult to card. There are usually some yellow streaks mixed in with the brown. Dip in warm tap water (100-110° F). Dry parts with compressed air and card again. The carding should be much easier after the water dip. Warm the parts again, put on several coats, dip in water, and card parts. If you want a more plum brown, heat water to 150° F or higher. You can get any shade of brown up to plum brown-black by raising water temperature.

NEUTRALIZING

Neutralizing Tools Required:

• Baking soda and water

• Container large enough to submerge the parts

When satisfied with metal finish, place parts in a container with a solution of baking soda and room temperature tap water (any concentration) for 5 minutes. Rinse parts, dry and coat with rust inhibiting grease (RIG) and let set for 24 hours.

TIPS

- During the whole browning operation don't touch the metal with your bare hands as you can leave contamination spots in the finish.

- If you use steel wool for carding make sure to buy oil free steel wool. It is available at fine wood working stores or on the internet.

- Garnet is preferred for etching as it is unlikely to imbed in the metal. This is only a concern on parts that rub against each other such as the bolt.

- Do not try to brown the ends of a barrel because you don't want to get any browning solution in the bore. Polish the barrel crown back to white after browning. I don't plug bores but I make sure I'm using fresh water when boiling barrels.

- If you don't have a boiling tank and are only going to do a few guns you can buy a piece of PVC pipe, glue a cap on one end, hang your barrel in the pipe and fill the pipe with boiling water each cycle.

- Parts can be strung on wire for boiling but don't wire brush the parts with the wire attached. I almost lost an eye when the wire brush grabbed the string of parts.

- After initial cleaning, a light scrub down with a 3M Scotch-Brite pad while in the water rinse is often helpful to insure that all cleaner residue is removed.

- Don't use WD-40 on fresh rust blued parts. The WD-40 can remove some of the finish.

EXPRESS BROWN#2

SLOW RUST #3

MARK LEE SLOW RUST BLUE #3 - INSTRUCTIONS

Wear safety glasses during all processes.

METAL PREPARATION

Metal Preparation Tools Required:

• Abrasive paper, cloth-backed 120 to 400 grit

• Selection of files or polishing stones

Remove pitting with files, polishing stones, or abrasive paper. Complete metal preparation using 320 to 400 grit abrasive.

DEGREASING

Degreasing Tools Required:

• Detergent (Simple Green® recommended)

• Scrub brush & Scotch-Brite pad

• Tongs or wire hooks

• Air compressor or paper towels

• Clean cotton gloves

• 2 Containers (1 for clean water & 1 for soapy water)

Degreasing is essential in getting fine results. Soak parts in hot soapy water using a cleaner such as Simple Green®. Scrub parts with a brush during the cleaning process. Remove parts from the cleaning solution with tongs or hooks.

Place cleaned parts in fresh hot tap water and lightly scrub with a Scotch-Brite pad to remove all residue. Remove from water and dry with compressed air or blot with paper towels. Wear cotton gloves while handling degreased metal parts. Do not touch cleaned parts with bare hands.

ETCHING (Optional)

Etching Tools Required:

• Sandblasting gun

• 150 grit garnet (aluminum oxide can be used)

Etching helps first applications take hold of base metal. Blast with 150 grit garnet at 30-40 psi. The polished metal will appear dull gray after blasting but the process of rust bluing will bring the sheen back. The blasting is best performed after degreasing, and parts should only be handled with clean cotton gloves.

Warning: Do not use glass beads as the beads produce different textures on hard and soft steel.

APPLICATION

Application Tools Required:

- Vinyl or latex gloves and cotton gloves

- Natural sea sponge, cellulose sponge, or cotton swabs

- Small glass or plstic container

- Steel wire brush (.003-.005") or oil free steel wool

- Stainless steel container for boiling distilled or deionized water. Tap water can be used in many parts of the country but it depends on the mineral content in your area.

- Humidity box

Pour solution into small glass or plastic container. Use vinyl or latex gloves during application. If you are using natural sea sponge or cellulose sponge, cut the sponge into one inch pieces. The object is to get the thinnest most even coat possible. Apply to barrel in long even strokes, keeping overlaps to a minimum. You will get a feel for how wet to get the sponge. The metal should be at room temperature before applying any slow rust solution. The first application will probably bead up on the metal unless the parts have been etched. Wipe over the coated parts with the sponge without adding any new solution and set aside for 15 minutes. The parts will start to turn green. Apply a second coat. This time the solution should wet out evenly on the steel. If not, rub the metal with the sponge again.

Now place the parts in your humidity box. I run mine at 90° F and 60% humidity. When parts are covered with brown rust, usually about 2 hours, remove from the humidity box and place in boiling water for 5 minutes. Remove the parts and dry. They will be covered with what looks like black soot. Wearing cotton gloves, use a wire brush or steel wool to remove the residue. The color will be silver, grey to black depending on the type of steel and whether the parts were pre-etched. After the parts have cooled to room temperature, apply another coat of bluing solution. Apply just one coat and place back into the humidity box. It will probably take about 5 hours for this coat of rust to form.

Boil in water to convert the brown rust to black rust and then card. Repeat this sequence three more times and the parts should be done. Never apply more than one coat of solution between boiling and carding except the first coat. When satisfied with the metal finish, oil parts and coat the bluing with rust inhibiting grease (RIG) and let set for 24 hours. The final neutralizing step below is unnecessary if you have boiled the last few coats in clean fresh water.

NEUTRALIZING

Neutralizing Tools Required:

• Baking soda and water

• Container large enough to submerge the parts

This step should be eliminated if fresh water was used to boil the last few coats. When satisfied with metal finish, place parts in a container with a solution of baking soda and room temperature tap water (any concentration) for 5 minutes. Rinse parts, dry and coat with rust inhibiting grease (RIG) and let set for 24 hours.

TIPS

- During the whole bluing operation don't touch the metal with your bare hands as you can leave contamination spots in the finish.

- After the first boiling and carding examine the metal under the light of a regular light bulb or sunlight. If you see any shade of brown or purple card the metal until the metal is silver, grey, or black. Applying coats over the top of bad color will lock it in. You usually won't see it happen again after the first boiling and carding.

- If you have a very small spot along a rib that doesn't want to take color, take a piece of new 400 grit paper and scuff the small area. The next coats should take.

- If you use steel wool for carding make sure to buy oil free steel wool. It is available at fine wood working stores or on the internet.

- Garnet is preferred for etching as it is unlikely to imbed in the metal. This is only a concern on parts that rub against each other such as a bolt.

- Do not try to blue the end of a barrel because you don't want to get any bluing solution in the bore. Polish the barrel crown back to white after bluing. I don't plug bores but I make sure I'm using fresh water when doing barrels.

- When placing parts in a humidity box let the metal come up to the temperature of the box before adding humidity so that water droplets don't form on the parts. If that does happen take parts out, boil, card, and recoat.

- Temperature and humidity can be varied so the rusting time can vary greatly. I usually run mine at 90 F with 60% humidity. Winchester was running their humidity box up to 150 F with 95% humidity with rusting cycles from 7 to 15 minutes. Parts need to be watched.

- A humidity box can be made of plywood. Heat the box with a heat lamp. Humidity can be added by hanging a wet cloth in the box. The box should have a small fan to keep the air moving which keeps the temperature and humidity consistent throughout the box. A temperature and humidity gauge can be mounted to the box. A window should be installed for watching the rust form. When the parts are covered with brown rust they are ready to be boiled.

- If you don't have a boiling tank and are only going to blue a few guns you can buy a piece of PVC pipe, glue a cap on one end, hang your barrel in the pipe and fill the pipe with boiling water each cycle.

- Parts can be strung on a wire for boiling but don't wire brush the parts with the wire attached. I almost lost an eye when the wire brush grabbed the string of parts.

- After initial cleaning, a light scrub down with a Scotch-Brite pad while in the water rinse is often helpful to insure all cleaner residue is removed.

- Sometimes carding with steel wool and water can blend a streak in the blued finish.

- Rust bluing can be lightly buffed with a loose muslin wheel and a compound used for mirror finishing. This adds a little sheen to the finish. This operation can be done just before applying grease or oil to the finished parts.

- Slow Rust #3 solution can be diluted up to 50% by adding distilled water. The purpose is to tone down the strength for certain steels or when trying to achieve a finer grain finish. I would only recommend diluting the solution to experienced finishers.

- Don't use WD-40 on fresh rust blued parts. The WD-40 can remove some of the finish.

SLOW RUST #3